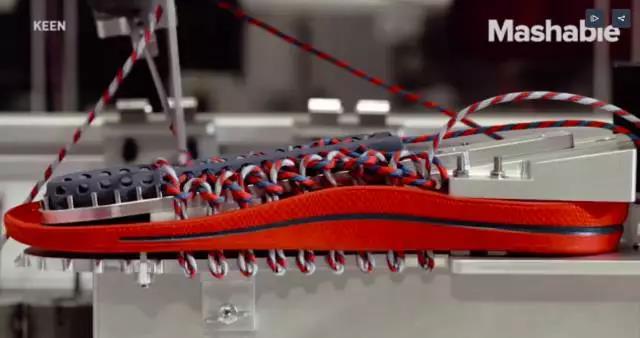

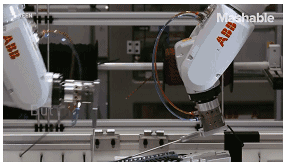

Thread and repeat... Under the "smart hands" of two ABB robots, a pair of threaded sandals can take only six minutes to form quickly. And two ABB robots make up the world's smallest shoe factory.

The world's smallest shoe Factory is a collaboration between Keen, an American outdoor shoe brand, and House of Design, an automation solutions company. By programming two ABB robots, the company created the smallest "Uneekbot Factory Store", a "portable" shoe Factory for its Uneek brand.

Not only can the robot produce custom-made sandals for consumers at any time and place, but it can run at full speed for only six minutes to select the correct spool and make a pair of shoes, which usually takes up to 12 minutes. When the robot is finished knitting, the shoemaker checks the quality of the sandals, adding embellishments to the vamp, and the customer waits no more than half an hour.

The concept of "two shoe ropes, one shoe mat" breaks the traditional shoe-making framework and also brings richer applications and unlimited innovation to industrial robots. By simply choosing the size and color of the shoes, customers can get custom-made sandals for up to half an hour and witness the process of making everything from materials to finished products.

When the factory is launched, two ABB robots work together to create custom Uneek sandals. With the fastest Settings, the robot can complete a pair of shoes in as little as six minutes.

UneekbotFactoryStore, a "portable" mini shoe factory, was unveiled at the Salt Lake City outdoor show in August 2016. It was also held for three days in harajuku, Tokyo, Japan.

While the shoes aren't 100 percent automated, the robots cut the entire production process in half and increased productivity. What's more, instead of shipping finished shoes, raw materials are shipped, reducing carbon emissions during shipping and reducing inventory pressure.

In the future, it's as if we can see industrial robots turning more invisible ideas into visible innovations!

This article comes from the network,forby the numerical control leather punching machine the automobile seat punching machine the united macro punching finishing release

Contact number: 13790532751